Table of Contents

Nano coating by fire

Nano coating by fire is the fastest but also the most fragile technique, because the layers remain fragile. Using a very soft brush, you can test if the layer is strong enough – run a soft brush gently over the nano-layers to see if they hold and there are no black particles are falling off. Depending on the result, you need to fire coat them again.

Technique

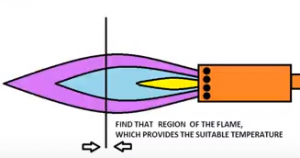

- Fire coating is done with a butane or propane torch. The temperature for a good nano coating is between 630-650ºC; the blue cone of the flame usually is in that temperature range.

- Generally you move the torch following the direction that the plasma should take. To nano plating the coils, for example, follow the sequence of the coil connections:

- The Terminals

- the gravitational coil in a clockwise direction

- the magnetic coil in anti-clockwise direction

- To make the rear side, the directions are reversed.

The torch must create a bright golden colour on the copper, which turn dark grey or black when cooling. Move the torch constantly to avoid overheating. It is important not to overheat the metal so that it does not turn red. If this happens, wait a while for the metal to cool down and restart the coating process. To obtain good results, the process is repeated 5-8 times with breaks to allow them to cool slightly.

The appearance of the rainbow colours is a sign that the temperature is not uniform – so go back again more slowly.

Fire plating is OK for energy applications (Magravs and capacitors) because it makes the nano layers more magnetic while plating with caustic solution makes them more gravitational. Fire plating also produces nano particles finer than caustic.

Barbecue technique

If you have no torch, you can nano coat by using the embers of a wood fire. Do not expose the parts to be coated directly to the flames but wait until you only see embers without flames.

- Place the object to be nano coated on the embers and wait until it is black and hot; be careful that the copper does not turn red as this removes the nano layer.

- Remove it from the heat and immerse it in warm water.

- Repeat this procedure 30 times.

Nano coating by Plasma

This is a third method of nano coating. It takes the longest time but provides the best results. When you install a Magrav in the house, the latter is nano coated over time. To make the nano plating by Plasma, you connect the wires to the Magrav or you lay the wires in the Magravs field, physically close.

Repair nano layers

Nano layers can be mechanically damaged (scratches or crushing by handling with tools or hands). Some areas on the plates may lose their nano plating during the GaNS production. This damage can be repaired – no need to throw away the materials!

Nano layers can be mechanically damaged (scratches or crushing by handling with tools or hands). Some areas on the plates may lose their nano plating during the GaNS production. This damage can be repaired – no need to throw away the materials!

Usually you only have to use the method by which the coating was originally made – and do it again. Small damages that can occur when making connections to coils or capacitors; those can be repaired with the caustic solution in which sugar has been added.