Table of Contents

Nano coating, hot caustic

The caustic solution is prepared by mixing the following substances:

- 4% NaOH (essential)

- 1% KOH (essential)

- 1% MgSO4 (optional)

- 1% Ca(OH)2 (optional)

For nano coating we use NaOH (caustic soda) and KOH (caustic potash). Potassium contains an isotope (K40) that is slightly radioactive, which gives extra energy to the process. The use of Mg and Ca salts will allow the nano layers to absorb a wider range of plasma fields.

Wear safety glasses and gloves.

- Clean the surface of the objects to ensure that they are free of oxidation, oil, fingerprints, etc. by immersing them in vinegar and salt for 15 minutes.

- Cover the entire bottom of the container with the dry caustic mixture.

- Place the objects to be coated on the grid or hang them up. Do not stack the copper pieces on top of each other and do not touch them once they are placed in the container. If you still have to handle them, be very careful not to damage the nano layers.

- Quickly pour boiling distilled water over the caustic into the container; no higher than the galvanized grid; close the lid and place in a warm place (30-40ºC) without disturbing for 48 hours.

- If you have not used a plasma capacitor, you must drain the current (see next chapter). When using a capacitor let the nano layers develop undisturbed for 1 month.

- At the end of the nano plating process, transition from the caustic environment to the ambient air gradually. Open the lid slightly and leave it in this position for 24 hours.

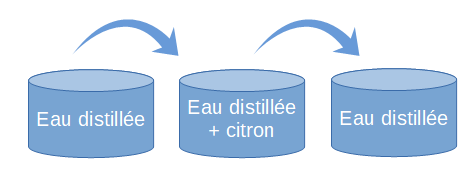

- Rinse the nano plated parts with distilled water to remove caustic from their surface. You can use 3 consecutive containers; in the second you can add a few drops of lemon juice.

- You can store nano plated parts in closed boxes, with a little moisture inside ( for example absorbent tissue soaked with PL-CO2).

Draining the current

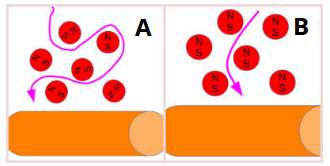

When using caustic for the nano coating process, the nano-particles are not aligned; they are chaotic and in this position they do not conduct the plasma efficiently (A). By draining the current of the nano-layers, we align the particles and the plasma passes more easily and directly (B).

Procedure

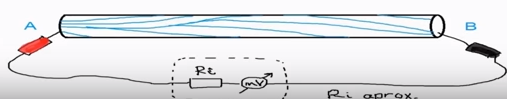

- Use a multimeter; select ‘millivolts’.

- Place the two terminals on each object in the places furthest from each other.

For plates: on diagonally opposite corners

For coils: on both coil terminals - Drain the power for 4-5 seconds with good intention!

- Repeat this procedure 4x every 6 hours or so for the plates to make GaNS; for the Magrav coils only once.

- After each drainage close the lid of the container.

If you do not have a voltmeter, you can also use a copper wire with a resistance (LED) in the middle; the latter will drain the current in the same way as the voltmeter (but you do not see it as the current is too small for the LED to light).